Theyll give your presentations a professional memorable appearance - the kind of sophisticated look that. Always keep the stressed areas of parts in compression 3.

Design Consideration For Casting

Avoid abrupt changes in the cross-section.

. In this video we will learn the following topicsa. The parting line should be identified on the casting drawingDetermining the position of the parting line is a critical step in the casting design. Select a casting process and material suitable for the part size mechanical properties etc.

General design considerations of casting are as follows. For example at our UK foundry we can produce castings. Parting line should be selected carefully so as to allow as small portion of.

Toy cars planes etc. Use of External devices for strengthen the part under tension. When Sheet metal parts have sharp corners try designing a fillet half of the material thickness.

Give fillet wherever the sharp corners are present. Design Consideration In Casting-General tips For Casting Design. In this video we will learn the following.

Design parts to be compression than in tension. 楊宏智台大機械系教授 Chapter Outline Introduction Design Considerations in Casting Economics of Casting Introduction Successful casting practice requires proper control of a large number of variables Flow of the molten metal in the mold cavities the gating systems the rate of cooling and the gases evolved would influence. Riser is defined as a reservoir for supplying molten metal to the casting cavity to compensate additional molten metal the liquid shrinkages taking place due to solidification.

A Casting can produce very complex. Design considerations of casting presentions in collage 1. Sharp corners are avoided to reduce the stress consideration.

Winner of the Standing Ovation Award for Best PowerPoint Templates from Presentations Magazine. Complex parts which are difficult to machine are made by the casting process using send mould Size of the send casting can be as small as 10g and as large as 200 k kg 2. Tabs must be at least 2 times the sheets metal thickness or 0126 32mm whichever is greater and can be no longer than 5 times its width.

Locate the parting line of the mould in the part. The cast iron is much stronger in compression than in tension. Avoid Concentration of Metal at the Junctions.

All Abrupt changes in section of the pattern should be avoided as far as possible. Design of component in compression than in tension. Therefore section changes in castings should be blended smoothly into each other.

O One runner is used for simple parts but-two runner systems can be specified for more complicated castings. Basic design considerations of the part and the entire casting process. Saurabh srivastava Shane alam Srikant kumar Sujeet kumar thakur Vinod rajbhar Vishvesh kumar pandey.

Casting is also heavily used in the toy industry to make parts eg. Provision of Fillet Radius. Parting line should be selected carefully so as to allow as small portion of the pattern as far as possible in the cope area.

Its impossible to create a final product without having these specifications down so we always ensure that our measurements and dimensions are correct before manufacturing the part. 4 Advantages of casting. The term casting is commonly used for metals and the term molding is used for plastics Examples.

Product Design Considerations in Casting - Geometric Simplicity Corners Section Thicknesses Draft. Up to 24 cash back Design Considerations in Metal Casting Mold and Gating System Design Directional Solidification and Troubleshooting In the previous sections we discussed the fundamental aspects of manufacturing parts by metal casting. Melting process Provides molten material at the proper temperature 3.

Riser Design Casting Definition. Curls dimension outside radius must be at least twice the materials thickness. Door handles locks the outer casing or housing for motors pumps etc wheels of many cars.

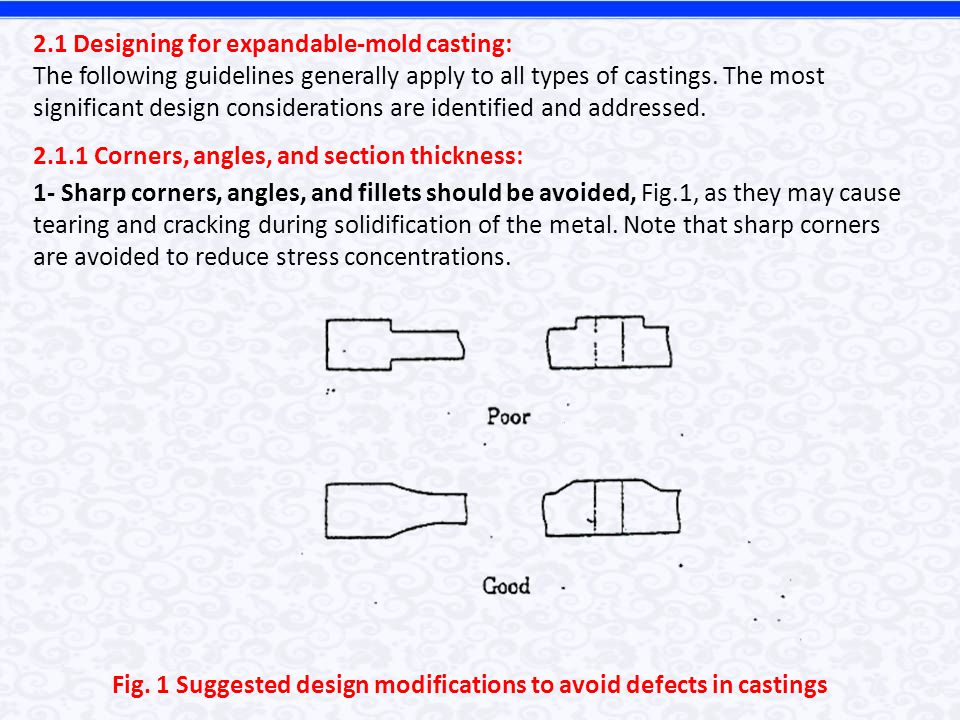

Design modifications to avoid defects in castings. Design Considerations in Casting - Runner design The runner is a horizontal distribution channel that accepts the molten metal from the sprue and delivers it to the gates. Construction and operating costs The cost of construction can be minimized by adopting a layout that gives the shortest run of.

Design Consideration In Casting. Design of component in. The general design considerations in casting include.

When designing casting the most important consideration is the effects of shrinkage during cooling. Design Consideration For Casting Mold cavity is produced having the desired shape and size of the part Takes shrinkage into account Single-use or permanent mold 2. The process by which a liquid material is usually poured into a mold which contains a hollow cavity of the desired shape and then allowed to solidify.

Avoid Very Thin Sections. Basic Requirements of Casting Processes Six basic steps of casting 1. O The runners are used to trap dross dross is a mixture of oxide and.

Different Methods to design Riser in casting is discussed. We covered the creation of patterns and the setup of the mold and gating system. It is very important for GATE mechanical exam.

The following considerations should always be kept in mind while designing a pattern. Avoid using sharp corners and angles as they act as stress raisers and may cause cracking and tearing during solidification. Basic design considerations of the part and the entire casting process.

Design Consideration In Casting-General tips For Casting Design. The solidified part is also known as a casting which is ejected or. There are many things to consider during the design stage of a casting such as size shape and weight.

General Design Considerations The development of a complete plant design requires consideration of many different factors such as. Design Consideration In Casting Ppt. Design the part so that the shape is cast easily.

Hence design the parts such that stressed areas of the parts are under compression rather than under tension. Construction and operating costs. Maximum parting line seam flash extension material is about 015.

Other important factors include metal flow and porosity. General design considerations of casting are as follows. Worlds Best PowerPoint Templates - CrystalGraphics offers more PowerPoint templates than anyone else in the world with over 4 million to choose from.

Which size of casting can be done. Shot Blast the Parts wherever Possible. Door handles locks the outer casing or housing for motors pumps etc wheels of many cars.

Mold cavity is produced having the desired shape and size of the part Takes shrinkage into account Single-use or permanent mold 2. We covered the creation of patterns and the setup of the mold and gating system.

Casting Design Materials And Economics Ppt Video Online Download

Design Consideration For Casting

Design Consideration For Casting

Design Consideration For Casting

Free Business Family Tree Template Powerpoint Presentation Ppt Family Tree Template Genealogy Templates Family Tree

Gunite And Shotcrete Are Products That Can Do Much More Than Pools Concrete Concrete Casting Water Cement Ratio

Fundamentals Of Casting Manufacturing Processes Ppt Video Online Download

0 comments

Post a Comment